Local Exhaust Ventilation,

regular testing of LEV equipment.

It is important (and a legal obligation) that LEV systems are tested regularly as engineering controls are routinely used to minimise potential exposure of employees to hazardous substances. We can help so contact us for a consultation

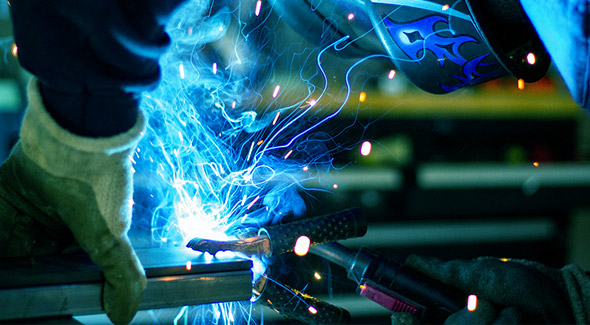

Local Exhaust Ventilation (LEV)

Protection against hearing loss

The Control of Substances Hazardous to Health (COSHH) Regulations requires employers to control exposures of substances hazardous to health to protect the employee. Regulation 9 of the COSHH Regulations 2002 (as amended) requires a thorough examination and test of local exhaust ventilation (LEV) equipment at least every 14 months (for the majprity of systems).

LEV Testing

The Health and Safety Executive document HSG258 "Controlling Airborne Contaminants at Work – A Guide to Local Exhaust Ventilation", defines Local Exhaust Ventilation (LEV) as “an engineering control system to reduce exposures to airborne contaminants such as dust, mist, fume, vapour or gas in a workplace.”

It is important (and a legal obligation) that LEV systems are tested regularly as engineering controls are routinely used to minimise potential exposure of employees to hazardous substances. Therefore, failure of these controls could have catastrophic consequences.

OHSL will provide a clear and concise report based on the Health and Safety Executive’s template. The report will include a summary detailing any actions required on the system and will give a clear opinion on whether the system is providing adequate control. A schematic diagram will be produced for each system detailing where the test points are located to aid repeatability. Photographs will be taken where appropriate and if client permission exists.

LEV Assessments

OHSL's LEV Assessments where appropriate will include the following:

- A thorough examination of all parts of the system

- Checks that any filter devices work correctly (e.g. shakers)

- Checks that monitors and alarms are functioning

- Inpsection of the air mover drive mechanism e.g. fan belts

- Checks for indications of effectiveness (e.g. deposited dust)

- Measurents of air velocities

- Duct velocities

- Capture velocities

- Face velocities

- Measurements of static pressure and at suitable test points

Qualitative assessments such as the use of smoke and a dust lamp may be carried out to check the capture effectiveness of the system and air flows in general.

Identify

We identify the potential hazards in the workplace.

Evaluate

We evaluate the potential risk involved.

Recommend

We recommend steps to mitigate the risk.

Our Solutions

Experience across a diverse range of disciplines

Occupational Hygiene Solutions Ltd. is a dynamic, professional consultancy service provider offering bespoke, quality occupational hygiene solutions to a wide range of industry sectors throughout the UK and Europe.